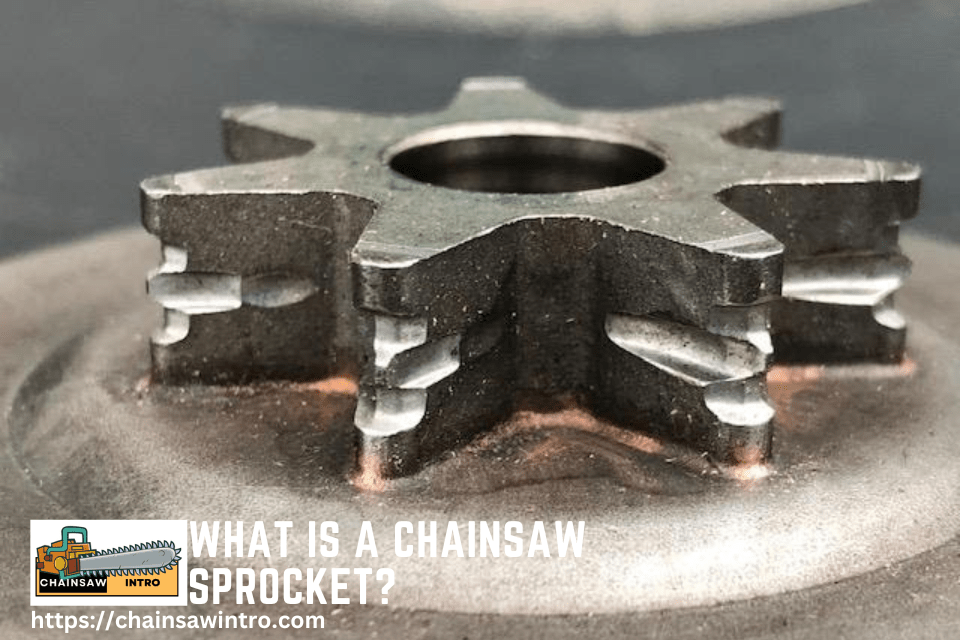

When most people think about chainsaw maintenance, they focus on sharpening the chain, keeping the bar oiled, or tuning the engine. However, there’s another critical part that plays a huge role in how your chainsaw performs—the sprocket. If you’ve ever asked yourself, “What is a sprocket on a chainsaw, and why does it matter?” this guide breaks down everything you need to know about this often-overlooked component.

Understanding the Chainsaw Sprocket

The sprocket is a small but essential part of a chainsaw’s drive system. It’s typically located at the end of the crankshaft and works like a gear that drives the chain around the bar. When the engine runs, the crankshaft turns the sprocket, which in turn moves the cutting chain at high speeds. There are two main types: the drive sprocket (connected to the engine/motor) and the nose sprocket (at the tip of the bar, in some models).

Without the sprocket, your chainsaw chain would have no way to rotate—and without chain movement, there’s no cutting power.

In short: the sprocket is the link between the engine and the chain, making it one of the most important components of the saw.

Chainsaw Sprocket Types – spur sprocket and rim sprocket comparison

Types of Chainsaw Sprockets

Chainsaws use two primary sprocket types, each with distinct features:

- Spur Sprocket: A single-piece sprocket bolted to the clutch drum, common in homeowner models like the Husqvarna 450. Durable and easy to replace, but wear on the teeth requires full replacement, costing $10-$30.

- Rim Sprocket: A two-piece system with a removable toothed rim that fits onto the clutch drum, found in professional saws like the Stihl MS 661. Rim sprockets are cheaper to replace ($5-$15) and allow easier chain swaps.

- Nose Sprocket: Located at the bar’s tip in replaceable-tip guide bars (e.g., Oregon PowerCut bars), this reduces friction and wear at the bar’s nose, improving chain movement for heavy-duty tasks.

Some chainsaws, like battery-powered Ego CS2005, use fixed spur sprockets for simplicity, while pro models offer interchangeable rim sprockets for versatility.

The Role of the Sprocket in Chainsaw Operation

The sprocket is integral to a chainsaw’s functionality:

- Power Transmission: In gas chainsaws (e.g., Echo CS-590), the engine rotates the clutch drum, which turns the drive sprocket to move the chain. In battery or corded models (e.g., Greenworks 80V), the motor directly drives the sprocket.

- Chain Speed and Efficiency: The sprocket’s tooth count determines chain speed. Fewer teeth (e.g., 6-7) increase speed for faster cutting, while more teeth (e.g., 8-10) provide smoother operation, ideal for precision tasks..

- Chain Tension and Stability: A properly aligned sprocket ensures the chain stays on track, reducing wear on the bar and chain. Misalignment or wear can cause the chain to jump off, increasing injury risks, per OSHA guidelines.

- Safety: A worn sprocket can lead to chain derailment or kickback, responsible for over 30% of chainsaw injuries, according to the CDC.

The sprocket works in tandem with the chain’s pitch (e.g., 3/8” or .325”) and gauge, requiring compatibility for optimal performance, as discussed on Reddit’s r/Chainsaw.

Signs of a Worn or Damaged Sprocket

A worn sprocket can compromise performance and safety. Look for these signs, based on FireAndSaw.com and YouTube tutorials:

- Worn Teeth: Rounded, chipped, or uneven sprocket teeth reduce chain grip, causing slippage or slow cutting.

- Chain Derailment: Frequent chain jumping or loosening indicates sprocket wear or misalignment.

- Vibration or Noise: Excessive shaking or grinding noises during operation suggest a damaged sprocket, per Reddit discussions.

- Poor Cutting Performance: If the chain produces fine dust instead of wood chips, even after sharpening, the sprocket may not be driving effectively.

- Visible Damage: Cracks, burrs, or excessive wear on the sprocket or clutch drum require immediate replacement.

Sprockets typically last 2-3 chain replacements (100-200 hours of use), but heavy use or poor maintenance can shorten their lifespan.

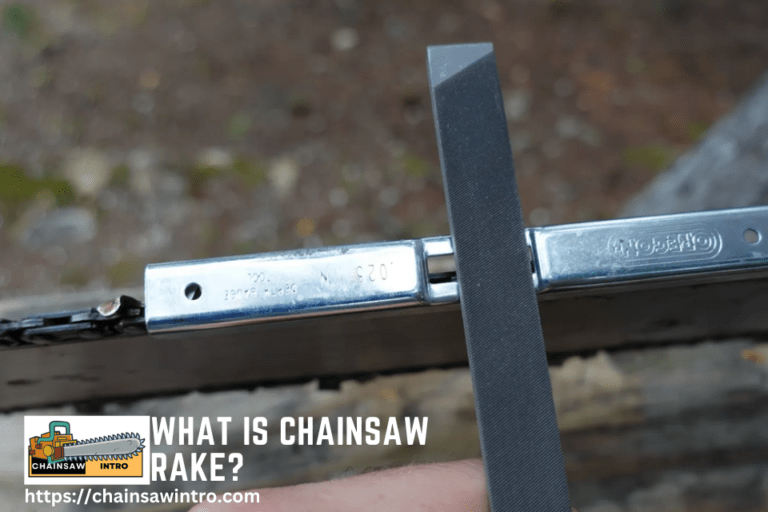

How to Inspect and Maintain the Sprocket?

Regular sprocket maintenance ensures smooth operation and extends chainsaw life. Follow these steps, based on 2025 Stihl and ArboristSite advice:

- Inspect Regularly: Check the sprocket every 10-20 hours of use or after replacing the chain. Look for worn teeth, burrs, or misalignment.

- Clean the Sprocket: Remove sawdust, oil, and debris from the sprocket and clutch area using a brush or compressed air to prevent wear.

- Ensure Proper Chain Tension: Over-tight or loose chains accelerate sprocket wear. Adjust tension so the chain pulls slightly but doesn’t sag, per our article on chainsaw maintenance.

- Lubricate Properly: Use quality bar and chain oil to reduce friction between the chain and sprocket, extending both components’ life.

- Replace When Worn: Replace spur sprockets ($10-$30) or rim sprockets ($5-$15) when teeth are rounded or chipped. Consult a professional for clutch drum issues, costing $50-$100.

For nose sprockets, replace the bar tip or entire bar ($20-$50) if the sprocket is worn, per Oregon’s 2025 manuals.

Tools for Sprocket Maintenance and Replacement

Invest in these tools for effective sprocket care, recommended by 2025 Amazon reviews:

- Sprocket Wrench: For removing spur sprockets ($10-$20).

- Clutch Removal Tool: Needed for accessing rim sprockets in pro models ($15-$30).

- Cleaning Brush: To clear debris from the sprocket area ($5-$10).

- Replacement Sprockets: Ensure compatibility with your chain’s pitch and gauge (e.g., 3/8” pitch, .050” gauge), available at Home Depot or Echo dealers.

Factors Affecting Sprocket Performance and Longevity

Several factors influence sprocket durability:

- Chain Compatibility: The sprocket must match the chain’s pitch and gauge. Mismatched components cause rapid wear.

- Usage Intensity: Heavy tasks like felling large trees (20+ inches) wear sprockets faster than pruning.

- Maintenance Practices: Neglecting chain tension or lubrication accelerates sprocket wear.

- Material Quality: High-end sprockets (e.g., Stihl or Oregon) use hardened steel, lasting 20-30% longer than budget options.

- Cutting Conditions: Cutting dirty or abrasive wood (e.g., near soil) increases wear on both chain and sprocket.

Sprocket Considerations for Different Chainsaw Types

Sprocket types and maintenance vary by chainsaw:

- Gas-Powered Chainsaws (e.g., Echo CS-590, Husqvarna 455 Rancher): Often use rim sprockets for easy replacement, supporting 16-20 inch bars.

- Battery-Powered Chainsaws (e.g., Greenworks 80V, Ego CS2005): Typically use fixed spur sprockets for simplicity, suited for 12-18 inch bars.

- Corded Electric Chainsaws (e.g., Oregon CS1500): Use spur sprockets, requiring less frequent replacement due to lighter homeowner use.

Always check the manufacturer’s manual for sprocket specifications, as brands like Echo or Greenworks may require specific sizes.

Conclusion

So, what is a sprocket on a chainsaw? It’s the critical gear-like part that transfers engine power to the chain, allowing the saw to cut wood. Though often overlooked, the sprocket directly affects cutting speed, chain life, and user safety.

Regular inspection and timely replacement of your sprocket will not only extend the lifespan of your chainsaw but also ensure safer, smoother, and more efficient cutting. Whether you’re a casual homeowner or a professional logger, paying attention to your sprocket is one of the best ways to keep your chainsaw at peak performance.

Frequently Asked Questions

How do I know if my chainsaw sprocket is worn out?

A worn sprocket will show visible grooves, notches, or sharp edges where the chain rides. You may also notice the chain slipping, uneven cutting, or strange noises while the saw is running.

Should I replace the chain and sprocket together?

Yes. It’s recommended to replace the sprocket after every 2–3 chains. Using a new chain on a worn sprocket causes premature wear and reduces performance. Matching both ensures longer life and smoother cutting.

What’s the difference between a spur sprocket and a rim sprocket?

A spur sprocket is a single-piece design integrated with the clutch drum, while a rim sprocket has a replaceable rim. Rim sprockets are generally preferred by professionals because they provide smoother chain movement and are cheaper to replace.

How often should I check my chainsaw sprocket?

Inspect your sprocket every time you sharpen your chain. Early signs of wear can help you replace it before it damages your chain or bar.

Does sprocket size affect performance?

Yes. A sprocket with fewer teeth increases torque but reduces chain speed, while more teeth provide faster cutting but lower torque. Most users should stick with the manufacturer’s recommended size for balanced performance.

Can I change my sprocket type?

Yes, you can switch from a spur to a rim sprocket (or vice versa) if the clutch drum allows it. Many professionals upgrade to a rim sprocket for longer lifespan and easier replacement.

How Often Should You Replace a Chainsaw Sprocket?

Most professionals recommend replacing the sprocket every 2–3 chains. In other words, after you’ve worn through two or three chains, you should replace the sprocket as well.

Why? Because an old sprocket with deep grooves will prematurely wear out a new chain, costing you more in the long run. Matching a fresh chain with a fresh sprocket ensures both last longer and perform better.

What is the function of sprocket?

The sprocket is an important part of the saw and it’s where the chain fits into. A worn or damaged sprocket can cause the chain to wear out faster and can also affect the cutting speed of your saw, so you want to make sure that your sprocket is in good working order. Here we will tell you everything about their workings including which ones work best for different kinds of cutting jobs!

Why Chain Sprocket is Used?

Chain sprockets are used in a variety of applications, including bicycles, motorcycles, cars, and industrial machinery. They are used to transfer power from one rotating shaft to another, allowing for the transmission of motion from the driver to the driven components. Chain sprockets are used to provide an efficient, reliable way to transfer power over a wide range of speeds and loads.

How Much Does a Chainsaw Sprocket Cost?

The cost of chainsaw sprockets can vary significantly based on the quality and size of the sprocket. Generally, you can expect to spend anywhere from $15 for a basic replacement sprocket to over $100 for a high-quality sprocket. The average price for a replacement sprocket is around $50.

How Long Does Chainsaw Sprocket Last?

The lifespan of a chainsaw sprocket can vary significantly depending on the type of saw, the quality of the sprocket, and how well it is maintained. Generally speaking, a high-quality chainsaw sprocket should last around 500 hours of use or two to three years with proper maintenance. However, low-quality sprockets may wear out within 100 hours of use or one year.

William C. Bozeman is a seasoned chainsaw expert and outdoor power tool enthusiast with over a decade of hands-on experience in tree cutting, forestry, and property maintenance. Having worked with leading chainsaw brands like Stihl, Husqvarna, and Oregon, Bozeman shares practical knowledge, safety tips, and honest reviews to help homeowners, DIYers, and professionals make informed decisions.